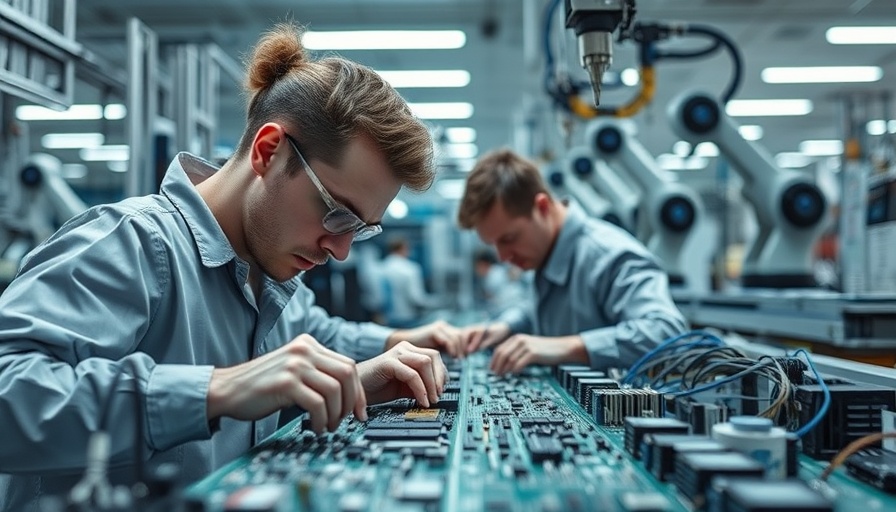

Understanding the Electronics Production Relocation Trend

As industry dynamics shift swiftly, over 35% of electronics companies are now considering relocating their manufacturing operations, according to recent industry insights. This trend comes at a time of significant upheaval marked by supply chain disruptions, changing trade policies, and security concerns that have caused executives to rethink their approaches to manufacturing and sourcing. In addition to looking for cost reductions, businesses are prioritizing resilience and reliability within their supply chains.

The Driving Forces Behind Relocation

Why are companies pivoting away from traditional manufacturing hubs like East Asia? Rising labor costs, increasing tariffs on imports from China, and a pressing need to safeguard supply chains against geopolitical uncertainties are key factors. For electronics firms aiming to lower production costs while maintaining quality, seeking reliable suppliers and alternative manufacturing locations in Vietnam, Mexico, and even the U.S. has become a strategic necessity. These shifts not only reduce exposure to risks but also open new avenues for innovation and efficiency.

The Economic Implications of Production Shifts

As manufacturers reassess their strategies, it’s crucial to understand how these relocation trends affect pricing, labor markets, and consumer availability. The competition for skilled labor is intensifying in emerging manufacturing regions, and companies must adapt to these realities. Executives must closely monitor economic indicators such as inflation rates that directly influence material costs, as well as the potential future impact on profit margins in the electronics sector. As tariffs and trade policies continue to evolve, preparing for disruptions becomes essential.

Strategies to Navigate Manufacturing Challenges

To successfully navigate these challenges, companies should consider implementing business cost reduction strategies, such as near-shoring production to minimize lead times and enhance supply chain reliability. Identifying and partnering with reliable U.S. suppliers can provide greater stability, particularly as global uncertainties impact pricing and availability. In response to the unpredictable nature of material costs, developing a robust forecasting strategy for the cost of goods sold will further empower executives to make strategic decisions backed by data.

Building a Resilient Future

Ultimately, adapting to the evolving landscape of electronics production relocation is about more than just cutting costs. It is an opportunity for manufacturers to future-proof their businesses against evolving geopolitical risks and tariffs. By incorporating actionable insights into supply chain management and reshoring strategies, companies can build resilience and ensure sustainable growth. As we look onward, executives must embrace the realities of this transitional phase, positioning their firms to reap the benefits of a restructured global market.

As the landscape of electronics manufacturing transforms, those at the helm must not only react to change but lead through it. Understanding these trends and implementing adaptable strategies will be key to achieving long-term success in the industry.

Add Row

Add Row  Add Element

Add Element

Write A Comment